Natural Gas Hot Water Boiler

Industrial 0.7MW 1.4MW 2.8MW Hot Water Boilers for Sale

Best selling product

Features

• Intelligent automatic control/Installation simple/Operation easy/long service life

• Application for Industry, Metallurgy, Energy, Construction, Petroleum and other fields etc.

• Thermal power: 0.7MW-14MW(955HP-19,100HP)

• Rated Work Pressure: 7bar-10bar(100psi-145..04psi)

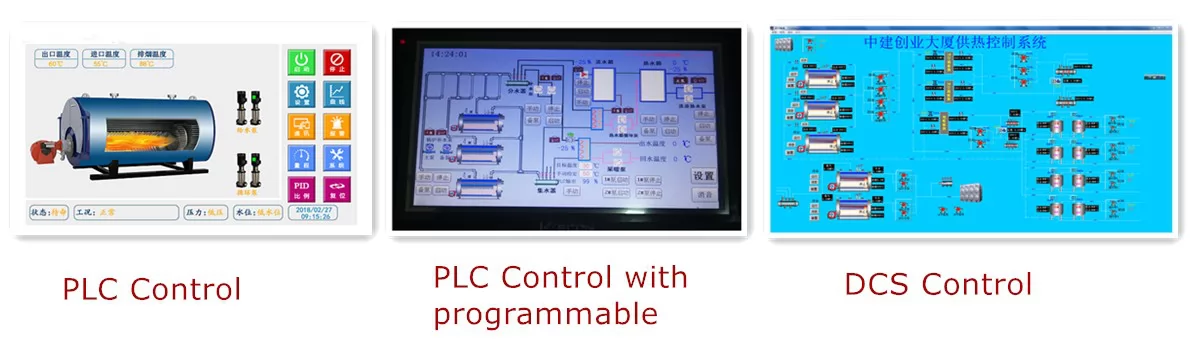

• Core Control Mode:PLC control, PLC+PC control, DCS control

• Thermal Efficiency(%):>98%

Description

Reviews(1)

Introduction of The Natural Gas Hot Water Boiler

Overview of the Natural Gas Hot Water Boiler

Gas Hot water boilers are mainly used for heating and bathing. The hot water boiler circulates the hot water in the heat preservation water tank through the hot water circulation pump, and heats the hot water in the water tank repeatedly to achieve the purpose of bathing; the hot water boiler circulates the hot water in the heating pipe through the hot water circulation pump and passes through the radiator. It can meet people's heating requirements; hot water boilers and hot water circulation pumps combined with heat exchangers can realize the dual functions of bathing and heating.Natural gas hot water boiler adopts boiler-shell type corrugated furnace structure, smoke three-pass with a wetback smoke-transfer chamber, spirally corrugated tube tech. The complete set product of the hot water boiler consists of burners, boilers, control systems, and accessories. This series of products are designed to be safe, reliable, efficient, energy-saving, and environmental protection. It also features convenient maintenance, long service life, automatic intelligent control, etc.

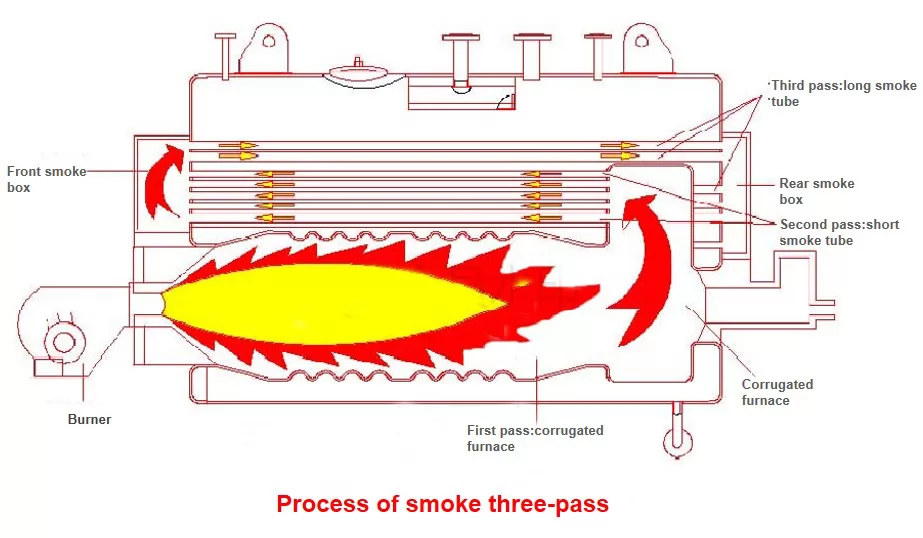

Structure of the natural gas hot water boiler

The main body of the natural gas hot water boiler adopts a single drum, horizontal, and wet back structure. The boiler drum is fixed on the body chassis through the fixed and movable supports at both ends and ensures the longitudinal thermal expansion of the whole boiler. The corrugated furnace constitutes the combustion chamber of the boiler, and smoke tube bundles are boiler convection heating, the smoke three-pass form.

Three pass flue gas of the gas hot water boiler as follows:

• The first pass--corrugated furnace

The operation of the boiler is automated. After the fuel is atomized by the burner, the torch formed fills the full corrugated furnace and transmits radiant heat through the furnace wall. This is the first return journey.

• The second pass--short threaded smoke tube

The high-temperature flue gas generated by combustion gathers in the re-combustion chamber and turns to enter the second return journey, that is, the flow of the threaded smoke pipe bundle area.

• The third pass--long smoke tube

It enters the smoke pipe through the front smoke box, and after convection, the temperature of the flue gas gradually decreases, then flows into the chimney through the economizer and condenser, and finally is discharged into the atmosphere.

Natural gas hot water boilers' features

★ The combustion chamber adopts the corrugated furnace, which reduces the thermal stress and improves the safety of the hot water boiler;

★ The boiler body adopts a wet back structure, which is safe and reliable;

★ The threaded smoke pipe enhances heat transfer and reduces the steel consumption of the body;

★ The boiler is fully automated, with automatic operation and interlock protection functions, and easy to operate;

★ The rear of the boiler adopts a spiral fin tube economizer, which reduces the exhaust gas temperature and has high thermal efficiency. The design efficiency is more than 90%, and the design efficiency of the condenser is more than 95%.

★ Boiler is the horizontal layout, compact structure, and small footprint;

★ The front and rear smoke boxes are easy to open, which is convenient for users to check and clean;

★ The flue gas side seal adopts a labyrinth double structure, the flue gas is not easy to leak, and the boiler room is clean and hygienic;

★ The boiler is shipped from the factory as a whole, which is convenient for transportation and a short installation period;

System of The Natural Gas Hot Water Boiler

Composition of Boiler System

·Combustion system

·Water system

·Control system

·Combustion system of the natural gas hot water boiler

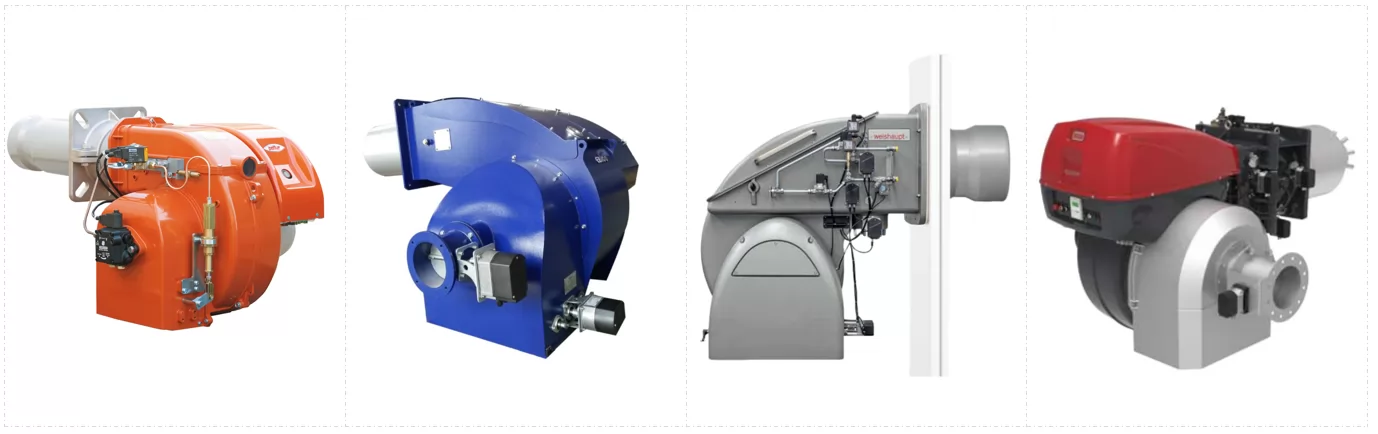

The combustion system supplies fuel to the hot boiler for heat generation.

The natural gas hot water boilers' combustion system equips with a burner and fuel device according to the fuel properties, thermal power, and pressure of the boiler.

Burner brands: Baltur, Riello, Weishaupt, Hofamat, Honeywell, Ecoflam, Cavallo, and so on.

·Water system of the natural gas hot water boiler

The water system consists of a make-up water part and a hot water part.

Make-up water part: make-up refers to the water that is provided to the boiler for hot water conversion. The make-up water channels water into the boiler and automatically controls it to satisfy make-up water requirements for the water system.

Hot water part: the hot water is part of the boiler responsible for collecting and regulating the hot water generated by the boiler. Valves and pressure gauges are used to monitor and regulate temperature and pressure.

The water system should be composed of the boiler's main body, rear heating surface(such as economizer, condenser, and so on. which are equipped according to the actual situation of the user), water treatment device, make-up water pump, Make-up pump constant pressure tank, decontamination device, plate heat exchanger, volumetric heat exchanger, circulating water pump, deaerator (choose to match) and so on.

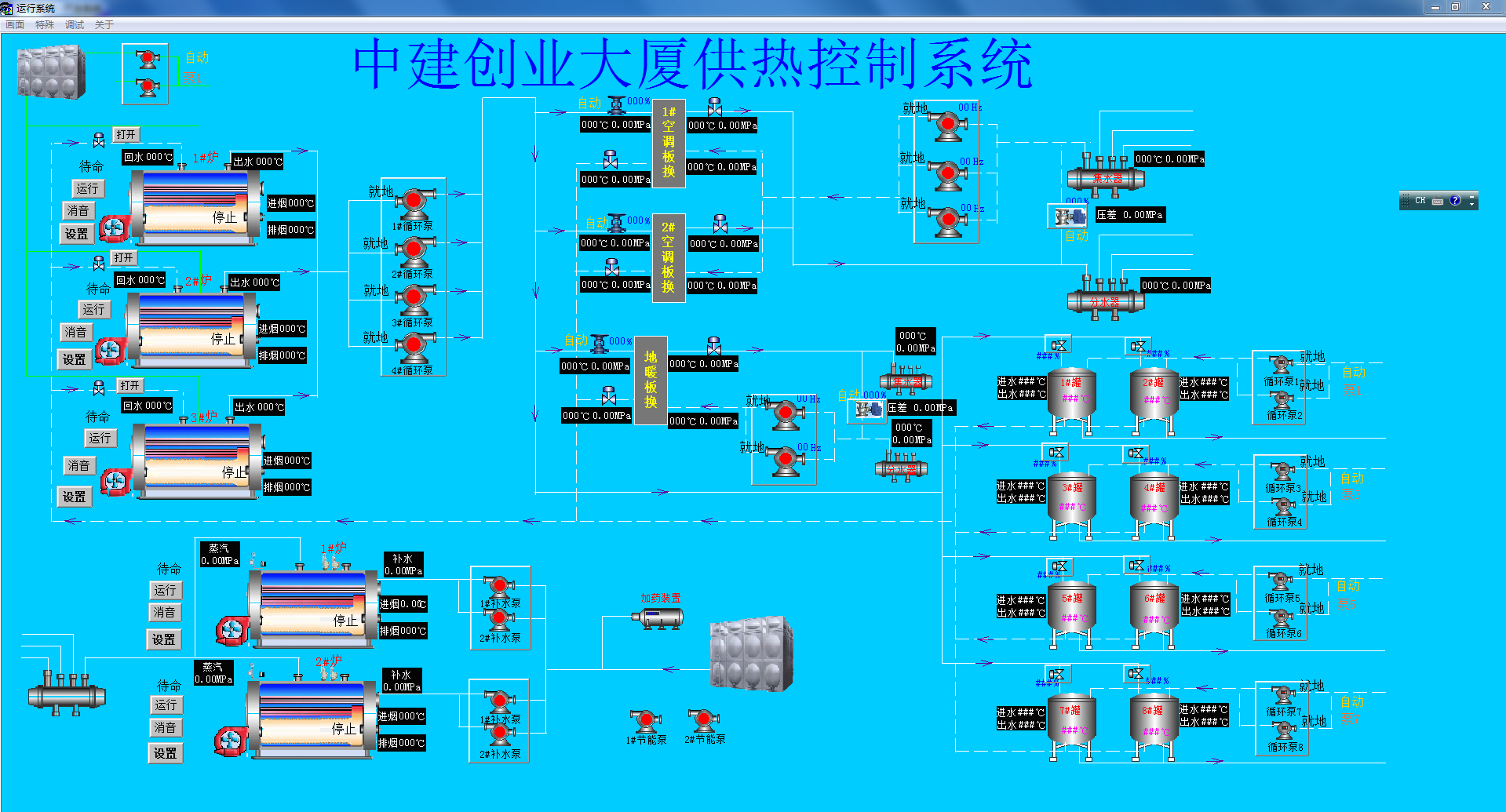

·Control system of the natural gas hot water boiler

The boiler control system is a collection of boiler electrical control components, a center for collecting and processing boiler operating signals, and an operation platform for sending execution instructions to each execution unit of the boiler.

If you want the boiler system to realize the IoT(Internet of Things) service for the boiler system, we can provide you with this service when designing the control system.

The IoT system for boiler system adopts a layered structure design, namely data collection layer(M BOX), cloud platform(M SERVICE), and application layer(MYZT application system).

Features of the industrial hot water boiler control system

• Indication of operating status, with start/stop button

• Feed water pump interlock

• Scheduled startup of operation

• Display of numbers of ignition and combustion

• High temperature /high pressure/ low pressure/ antifreeze/ burner stop alarm functions

• Display of malfunctions

• Self-interlock during power down for protection

• Date/information collection, analysis, and storage function

• Password protection of the controller

• Modbus RS485 interface, connection to an upper control system or DCS system of the plant from multiple boilers

The control system of the natural gas hot water boiler provides the control of boiler water level, pressure, burning, safety protection, and so on.

Control principle: Through the real-time data collection, monitoring, and processing of boiler water level, pressure, flue temperature, and burner, the purpose of intelligent and safe operation is achieved.

★The Core Control Mode of the steam boiler system: MCU control(Microcontroller unit), Integrated controller (All-in-one PLC, not programmable), PLC control(programmable), PLC+PC control, DCS control.

★ Standard Control Content: boiler water level, steam pressure control, alarm, and interlock, and set up an automatic control system for combustion start and stop.

★ Steam Boiler Control Modes of Operation: Automatic and Manual

a) The boiler in automatic mode is in a fully automatic operation state,

b) Manual mode: The operation of the boiler equipment is controlled by manual operation. Under normal circumstances, the boiler should operate in an automatic operation state. In special cases, it will be required to switch to the manual state.

★ Control system detection data sources: burners, temperature sensors, pressure transmitters, pressure controllers, liquid level gauges, flow meters, electric regulating valves, and other remote instrument valves.

Control cabinet kinds for coal fired steam boilers: wall-mounted control cabinet, podium control cabinet, MCC vertical control cabinet, piano-style control cabinet, positive pressure explosion-proof control cabinets, and three-proof control cabinet. likes follow:

Company Profile

CN BOILER ENGINEERING SOLUTION LLC is a comprehensive service provider of thermal energy systems in China, devoted to providing customers with one-step thermal energy system solutions by safe, save energy, environmentally, intelligent, and reliable. Main products include industrial boilers(hot water boilers, steam boilers, thermal oil boilers, waste heat boilers, and CFB boilers), steam generators(electric steam generators, electric hot water generators), intelligent control system by PLC control, PLC+PC control or DCS control, remote instrument and valves and so on. The control system includes industrial boiler control system(oil fired boilers, gas fired boilers, biomass fired boilers, coal fired boilers, electric boilers, waster heat boilers, CFB boilers), PLC deaerator control system, condensate recovery system, reactor control system, heating exchanger control system, hot air boiler control system etc.

5.0

/5

Showing

6

of

1

reviews

Most recent

Top Reviews

James -

US

5/5 stars

Nov 13.2023

After the boiler equipment provided by CN Boiler is put into operation, it has reduced production energy consumption and saved more money; it also provides a stable heat source for our hotel. At the same time, it can help us provide our customers with a better experience.

Read more

Your rating

Your review *

Name *

Enter your Name

Email *

Enter your Email

Upload Image

Notice: Ensure your image is no larger than 200KB before uploading.

Submit

Contact Us Now

Enter your inquiry details, We will reply you in 24 hours.

Name can't be empty

E-mail can't be empty

Company can't be empty

Phone can't be empty

Phone

Products can't be empty

Products you want

Message can't be empty

Verification code error

Clear

People who viewed this item also viewed