Dependable Boiler Remote Instrument Supplier in China

26 years of unbroken supply and practice, committed to providing solutions that stand the test of time.

Boiler Instrument Supplier

Customer Feedback

"The precision of this water level controller is unmatched. It's incredibly dependable and has eliminated false alarms. Our boiler efficiency has noticeably improved since installation."

Edward

Technician

"The zirconia oxygen analyzer is incredibly accurate and dependable. Its real-time data has improved our combustion efficiency, reducing fuel costs significantly. The robust design ensures durability, even in harsh industrial environments. Highly recommend it to anyone looking to optimize their process!"

Williams

User

"The boiler differential pressure transmitter is incredibly reliable and precise. It provides accurate readings even under extreme operating conditions, which has helped us maintain optimal boiler performance. Installation was straightforward, and its durability ensures minimal maintenance. Highly recommended for any industrial setup!"

Anna

Boiler Technician

"The boiler differential pressure transmitter is a high-quality device that delivers reliable performance. Its advanced features and durability have made it a critical part of our boiler operation."

Patrick

Purchasing Manager

"The magnetic float level gauge is incredibly durable and reliable, even in extreme conditions like high temperatures and pressures. It's perfect for our industrial needs."

Atiq

Purchasing Manager

"Using this magnetic float level gauge has simplified our monitoring process. It’s reliable, robust, and delivers precise water level readings, ensuring the safety of our boiler operations."

Mathew

Maintenance staff

Why Choose Us

FAQ

- The differential pressure transmitter measures the pressure difference between two points in a boiler system, typically to determine water levels or monitor flow rates. It ensures accurate readings for safe and efficient boiler operation.

- Differential pressure transmitters commonly output a 4-20mA signal proportional to the pressure difference. This signal is used by control systems to monitor and manage boiler operations.

- Answer: The transmitter should be mounted lower than the pressure tapping points to ensure accurate readings. Pipes connecting to the transmitter should be inclined, insulated, and kept parallel to minimize thermal expansion effects and prevent freezing in colder environments.

- Regular zero-point calibration, cleaning of impulse lines to prevent blockages, and inspection of seals and connections are crucial. Condensation water in the chambers should also be drained periodically to maintain accuracy.

Modern automatic controllers provide:

- Real-time monitoring and adjustments.

- Enhanced safety through intelligent alarms and shutdown mechanisms.

- Improved efficiency by optimizing feedwater control.

- Remote monitoring and diagnostics via PLC or IoT integration.

- The zirconia oxygen analyzer is used to measure oxygen levels in combustion flue gases. It helps optimize combustion, conserve energy, and reduce environmental pollution.

- It uses a zirconia element as a solid electrolyte. When the oxygen concentration differs on the inside and outside of the zirconium tube, it generates an electromotive force proportional to the oxygen level, which is measured and analyzed.

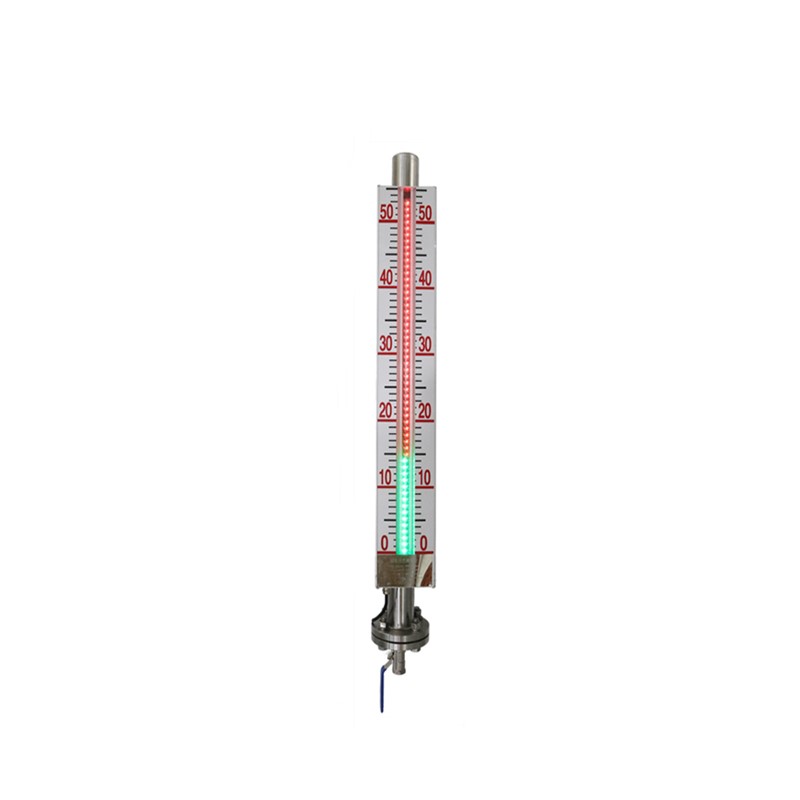

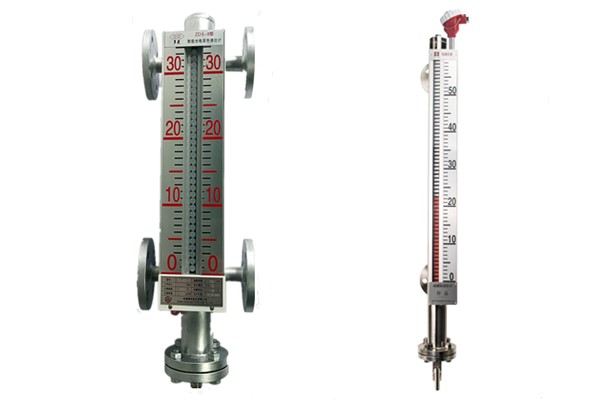

- The magnetic float type level gauge operates on the principle of buoyancy and magnetic coupling. As the magnetic float inside the measuring tube rises or falls with the liquid level, the external magnetic flip plates rotate 180° to indicate the level. Red indicates a rising level, and white indicates a falling level.

- Key features include: High sealing and leak-proof design / Operates without power supply / Suitable for high temperature, high pressure, and corrosive environments / Can measure interfaces of two different density media.

- The standard measurement range is 0–6000 mm, operate at temperatures ranging from -190°C to 550°C and withstand pressures up to 40 MPa.It can be customized ranges can be negotiated for specific applications

Precision Control, Maximum Efficiency – Power Your Boiler System with Smart Solutions!

Our team consists of sales, design, sample production, order tracking, logistics, quality inspection, and accounting professionals, ensuring one-stop service for our clients. Whether it's product customization or technical support, we are here to meet your needs.

Our products include:

-

Boiler Control Panels

-

Boiler Differential Pressure Transmitter

-

Boiler Water Level Controller

-

Temperature Sensor

-

Zirconia Oxygen Analyzers

-

Magnetic Float Level Gauges